SSD vs. HDD - What's the difference?

Think of any computer you have purchased over the last decade or two and, chances are, it was a system whose storage requirements were served by a hard disk drive (HDD). Armed with fast spinning disks and various moving parts, HDDs have been the dominant storage device in personal computing for quite some time but are now being replaced in certain environments where a modern-day solid-state drive (SSD) is a better fit.

Designed as a successor to the hard disk, an SSD technically contains no 'disks' in the traditional sense and instead uses flash memory modules to store data. This fundamental change means SSDs have no moving parts and are consequently more robust - there are fewer small parts at risk of failure, heat build-up is minimised, there is no perceptible noise, and flash-based drives are inherently more resistant to vibration and shock.

Crucial: SSD vs. HDD Shakedown

Durability is one of the reasons why SSDs are becoming increasingly popular in mission-critical environments, yet there are obvious benefits to mainstream users, too. With no spinning platters or magnetic heads, SSDs make it easier for a computer to locate data: loading times are greatly improved, PCs boot much more quickly and a near-instant responsiveness is made available to machines of all shapes and sizes.

On top of the speed and reliability enhancements, SSDs are typically smaller than their HDD equivalents, making them a better fit for today's ultra-thin laptops and mobile devices. And last but not least, SSDs are typically more power efficient, leading to improvements in battery life when compared to normal HDD-based solutions.

The one caveat is cost. Though the gap is closing, HDDs continue to offer more gigabytes-per-pound when compared directly to SSD alternatives. Yet for many users the benefits of superior solid-state storage will far outweigh the higher initial cost, so how do the drives work and what details do would-be buyers need to be aware of?

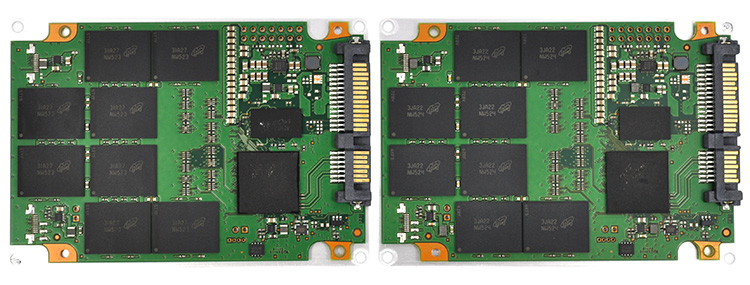

Topology of an SSD – Controller and NAND

SSDs are generally made up of a type of nonvolatile flash memory known as NAND. These solid-state chips don't require power to retain information written to them, and they define the overall capacity of the drive. Interfacing with a separate controller that acts as a go-between between the NAND modules and operating system, the quality of NAND, controller and associated firmware predicates overall performance.

As you might expect, the overall cost of an SSD can also be directly linked to the NAND memory within: higher-capacity drives using the latest-generation NAND technology typically attract a higher premium.

At the time of writing, NAND memory production is led by Samsung, Toshiba, and Intel/Micron (IMFT). Cutting-edge SSDs such as the Crucial M500 use 20nm NAND with MLC (multi-level cell) technology that, as the name suggests, increases capacity through using multiple bits per cell. This implementation, coupled with a shrink in manufacturing process, has enabled SSDs to ship with higher capacities than ever before, and 1TB capacities are now readily available in a small 2.5in form factor.

The downside of using more bits per cell is that speed and reliability can be compromised, so SSD manufacturers need to balance the competing interests of capacity, reliability, speed and price when thinking about solid-state drive production. Enterprise-class drives, for example, use NAND of the faster, more expensive SLC (single-level cell) variety.

NAND memory defines SSD capacity and potential performance, but the drive's controller has a huge impact on how efficiently the NAND is used. One can think of the controller as the brains of the outfit.

Appreciating the complex job entrusted to the controller - acting as the regulator between NAND and the operating system - choosing the appropriate model is critical with respect to overall performance.

The chip's purpose is to leverage the performance from the NAND by a technique known as multi-channel aggregation and to keep traffic (data) moving in and out of the SSD, at peak speeds, without stalling performance.

There are multiple companies that manufacture controllers for SSDs, including Marvell, Intel, Samsung and SandForce. Each controller can be programmed via firmware updates, with optimisation proving to be an ongoing process for the SSD industry.

Driving innovation, recent controllers such as the Marvell 88SS9187 (pictured above in a Crucial M500) have offered support for the SATA 6Gbps interface, a multi-channel interconnect for onboard NAND, data transfer speeds of up to 500MB/s, and an array of security improvements that include 256-bit AES encryption, as well as TCG Opal 2.0 and IEEE-1667 compliance.

Different types of NAND – SLC, MLC and TLC

As we know, NAND is a nonvolatile form of flash memory that can be electrically erased and reprogrammed. With no mechanical parts, this revolutionary technology - first introduced in the '80s - has soared to popularity and is today found in everything from small mobile phones to large industrial robots.

Today, the SSD market is served by three primary forms of NAND: single-level-cell (SLC), multi-level-cell (MLC) and triple-level-cell (TLC). As the names suggest, SLC is capable of storing one bit per cell, compared to two for MLC and three for TLC. So what are the pros and cons of each?

Let's start with the obvious. By storing two- or three-times the number of bits per cell, MLC and TLC memory are able to offer higher densities - meaning greater capacity at a lower cost. That's arguably the most important factor for most consumers in the market for an SSD, but there's more to solid-state storage than cost alone.

Micron: 25nm Triple-Level-Cell NAND

As explained by Kevin Kilbuck, Micron's director of strategic NAND marketing, there are some trade-offs to MLC and TLC memory: "the performance and the endurance, as measured in the number of times you can program the NAND, tend to degrade as we increase more bits per cell."

What this means is that, while drives featuring multi-level-cell technology can be significantly cheaper to produce, they are also more prone to wear when compared to SLC equivalents. For example, while an SLC cell is typically rated at 100,000 erase/write cycles, an MLC cell might offer only 10,000 erase/write cycles - a 10x reduction.

In order to ameliorate long-term reliability concerns, manufacturers have introduced various wear-leveling technologies designed specifically for MLC and TLC solutions. These innovations - typically integrated into an SSD controller - help move program/erase cycles around the drive to ensure even wear, and can also include redundancy (where whole cells are reserved to replace any others that fail) and on-the-fly compression (to reduce the amount of data written to the drive).

The key takeaway is that MLC and TLC solutions offer the best mix of price and performance for consumer drives, whereas premium SLC models are best-suited to industrial/enterprise environments where data is constantly being refreshed as opposed to just stored.

Form factors and interfaces

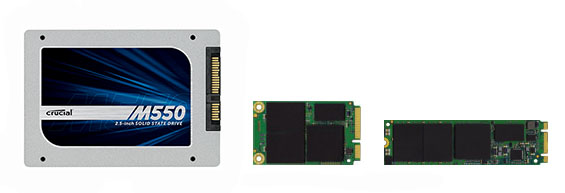

There's plenty of variation to an SSD's underlying components, but compared to a mechanical hard disk with multiple moving parts, a solid-state drive is a relatively straightforward affair. An SSD is, for all intents and purposes, a collection of flash memory chips and a controller installed on a simple printed circuit board (PCB).

It is this unsophisticated configuration that allows modern SSDs to be packaged in a choice of form factors. The most common of these is 2.5in, where an SSD's PCB is encased in a simple metal enclosure that mirrors the drive dimensions of a traditional 2.5in hard disk.

Making the most of higher-density NAND, newer form factors are able to offer the speed of SSD technology and good capacity in much-smaller packages. Mini-SATA, or mSATA for short, uses a miniaturised version of the SATA connector to deliver bare-board drives that measure just 51mm x 30mm in size and are ideal for use in laptops and other mobile devices.

mSATA, however, can be seen as merely a stopgap. In order to meet the needs of future devices, an SSD-optimised form factor dubbed M.2, previously known as NGFF, has been introduced to bring flexibility in size and interface, allowing small bare-board SSDs to offer greater capacities and a choice of high-speed SATA or PCIe interfaces.

M.2 slots will be featured on next-generation desktop motherboards from Intel and AMD, and the form factor is well-placed to take full advantage of the performance potential of SSDs, with the available PCIe interface offering speeds well in excess of 1,000MB/s.

Crucial M550 Product Range |

||||||

|---|---|---|---|---|---|---|

| 2.5in | Capacity |

Part Number |

Sequential Read (MB/s) |

Sequential Write (MB/s) |

Random Read (IOPs) |

Random Write (IOPs) |

128 GB |

CT128M550SSD1 |

550 |

350 |

90k |

75k |

|

256 GB |

CT256M550SSD1 |

550 |

500 |

90k |

80k |

|

512 GB |

CT512M550SSD1 |

550 |

500 |

95k |

85k |

|

1 TB |

CT1024M550SSD1 |

550 |

500 |

95k |

85k |

|

| mSATA | Capacity |

Part Number |

Sequential Read (MB/s) |

Sequential Write (MB/s) |

Random Read (IOPs) |

Random Write (IOPs) |

128 GB |

CT128M550SSD3 |

550 |

350 |

90k |

75k |

|

256 GB |

CT256M550SSD3 |

550 |

500 |

90k |

80k |

|

512 GB |

CT512M550SSD3 |

550 |

500 |

95k |

85k |

|

| M.2 | Capacity |

Part Number |

Sequential Read (MB/s) |

Sequential Write (MB/s) |

Random Read (IOPs) |

Random Write (IOPs) |

128 GB |

CT128M550SSD4 |

550 |

350 |

90k |

75k |

|

256 GB |

CT256M550SSD4 |

550 |

500 |

90k |

80k |

|

512 GB |

CT512M550SSD4 |

550 |

500 |

95k |

85k |

|

Crucial has been at the forefront of SSD development and continues to drive innovation by adopting the latest available form factors. The manufacturer's latest SSD range - the M550 - launches in 2.5in, mSATA and M.2 variants right from the get-go.

Choosing the right SSD for you – factors to bear in mind

The benefits of solid-state storage are clear for all to see, and the rapid development of this game-changing technology has taken us to a point at which it is hard to differentiate between consumer drives based on performance alone.

Most 2.5in solutions are capable of saturating the SATA 6Gbps interface, and all SSDs offer the same core benefits: increased durability, incredible sequential performance, near-instant response times and more efficient operation.

Given that straight-line performance is arguably no longer the key differentiator, manufacturers are using other avenues such as brand recognition and customer support to stand out from the crowd. As a brand of Micron - one of the largest NAND manufacturers in the world - Crucial is able to tout in-house development and a commitment to SSD reliability testing that few other vendors can match.

A wide range of Crucial SSDs are available to purchase from the official Crucial Store.

For full disclosure, this editorial was sponsored by Crucial.