Floor 7 - SMT – part 2

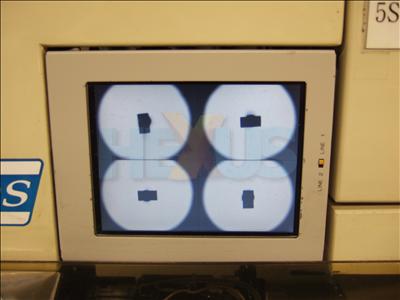

Another Fuji high-speed component-placer which also positions small SMT components onto the board. This higher-end model even seems to have an optical monitoring screen that displays what the machine is picking and placing. Technology, huh?

Conveyor belts either side of the machine feed the boards from piece of equipment to another.

Here's a Fuji medium-speed component-placer, and several of these are used to place the larger SMT components onto the PCB. You can't rush this stage.

Another Fuji medium-speed component-placer. This one is placing BGA chips onto the board.

Two of the different reflow ovens used in the SMT process to bake the solder paste - and, therefore, components - on to the boards.

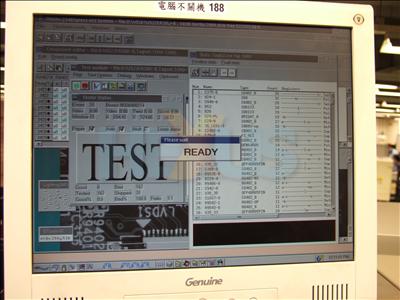

The Orbotech Trion Auto is an optical inspection machine. This automatically checks the board for missing or damaged components and bad solder joints.

More expensive hardware in the form of the HP Testjet in-circuit tester.