Floor 7 - SMT – part 1

A quick overview of the machines used during the SMT process at Nan-Ping.

Amusing instructions like this are placed all around the factory floors.

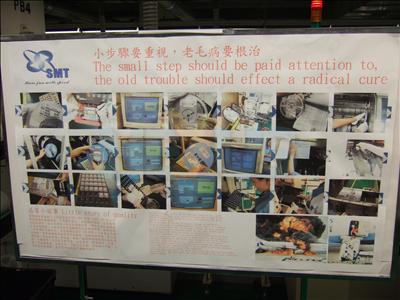

Yet more amusing (if somewhat important) advice. Seeing as most of it’s in English, it makes me wonder if these have just been left here to amuse visitors to the factory. Based upon my own reaction and those of the other visitors in the group I’d have to say it seems to work well.

In addition to having to wear unfashionable shoe bags, additional dust prevention is provided by the air shower.

SMT (surface-mount technology) area overview. It's a big, big place.

Starting the SMT production line, the PCBs are loaded into the first machine.

The boards are first sprayed with solder paste using this DEK solder paste printer.

DEK solder-paste printer status display.

Then the Fuji high-speed component-placer puts the smaller SMT components such as resistors and LEDs on the board. This machine can place approximately 10 components per second on to the PCB. Notice the speed of the machine in the first shot, running too fast for the camera to capture? It takes at least a 1/60-second shutter-speed to capture it clearly (ed. excuse for poor photography ;)