Floor 5 – DIP – part 1 (Motherboards)

Now we've got a product that looks somewhat akin to what you receive in the box.

The larger components have been machine-fed on to the mainboard and been inserted ready for wave soldering.

Optical inspection lamp and lens for solder-side inspection.

The finished product after touch-up, solder-side inspection and heat-sink assembly, but we're getting ahead of ourselves.

Going back a step or two, here's a bunch of motherboard components awaiting picking for the production line.

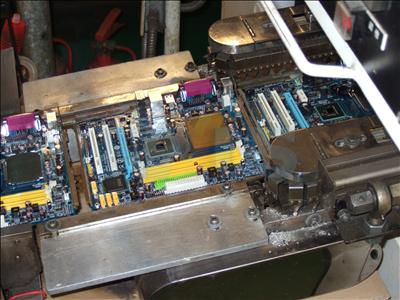

And the start of the manual insertion process. First step is to mount the board on the frames which are used to support it during the wave-soldering process.

Different stages of the manual insertion process.

Final checks on the correct insertion of the components before they enter the wave-solder machine.

Motherboards about to enter the wave solder machine.

Here's the huge wave-solder machine that is used to solder the DIP components to the board.

Motherboards after they’ve just exited the wave-soldering machine and getting made ready for touch-up and heatsink assembly.

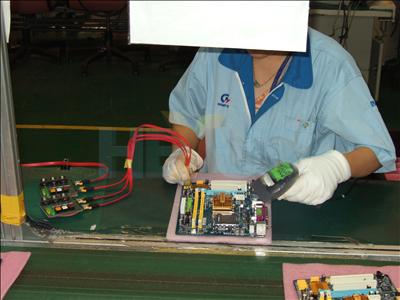

Heatsink assembly for the motherboards, all done manually and by hand.

Near the end of the line, literally, here's an employee giving the board a once-over.

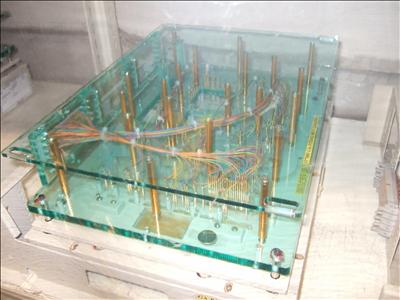

To make sure everything works as expected, a raft of in-circuit testers is employed.

There are specific ICT test fixtures for various motherboards, because you need to test various points that aren't perfectly aligned across the motherboard range. This one is for the GA-P35DS3 rev. 2.8a.

Board setup for function test.

I can’t read Chinese but I’d guess that these are the stats for the current production line, insofar as total number to be produced, number currently produced before inspection, number passed inspection, number failed inspection, etc.

Boxes of finished products awaiting PQC (Process Quality Control).